MetallographIC Laboratory

ACCREDITED TESTING LABORATORY ACCORDING TO STANDARD ČSN EN ISO/IEC 17025:2018

The Metallography Laboratory focuses on the research of transformation processes and microstructure evolution during thermal and thermo-mechanical processing and on the study of high temperature behaviour of materials. It is also intensively involved in the analysis of metal powders and microstructures formed by additive manufacturing. We use state-of-the-art microscopes and instrumentation for in-situ deformation and temperature experiments and for the measurement of local mechanical properties.

Accredited tests:

- macro and microstructure tests

- determination of elements by the method of optical emission spectrometry

- microhardness test

STRUCTURAL ANALYSIS

One of the main activities of the laboratory is structural analyses, which include checking micro-purity, determining grain size, powder size distribution, surface layer thickness, checking the micro- and macro- structure of castings, forgings, welds, checking microstructure after heat treatment, thermo-mechanical processing and additive manufacturing. Activities also include local (EDS) and overall chemical composition, checking hardness and microhardness (including changes and mapping).

DETERMINING THE CHARACTER AND CAUSES OF MATERIAL FAILURE

Detailed fracture surface analyses complemented by macro and microstructural analyses are part of a comprehensive material failure analysis. These analyses are used to determine the cause of non-integrity, defects, premature fracture of components and to assist in solving manufacturing problems, etc.

EVALUATION OF SURFACE LAYERS, COATINGS AND COATINGS

Evaluation of coatings using detailed metallographic analyses, changes in chemical composition, dry and lubricated pin-on-disc wear evaluation, pressure testing of micro-pillars and thermographic evaluation of crack initiation under mechanical loading, as well as micro-hardness changes and mapping.

LABORATORY EQUIPMENT

Zeiss Auriga Cross Beam SEM-FIB

This is an ultra-high resolution scanning electron microscope with integrated ion beam. The microscope is also equipped with BSE, EBSD, EDX and STEM detectors and can make 2D and 3D chemical composition maps. The ion beam can be used to prepare micro-samples from selected regions of a structure, which can then be subjected to tensile, compression and bending tests in-situ.

Deformation table with heating up to 1200 °C

Deformation and temperature experiments can be carried out directly in our Zeiss EVO 25 scanning electron microscope. During the experiments, changes in microstructure, recrystallization and phase transformations can be monitored and changes in crystal lattice, texture, etc. can be quantified with the EBSD detector.

Anton Paar TRB3 Tribometer

Wear tests using the pin/ball-on-disc method with the ability to measure the coefficient of friction and subsequent wear evaluation in accordance with ASTM G99, ASTM G133, and DIN 50324. Wear can be evaluated by weight loss or by volume of material removed (from the groove shape), either dry or lubricated.

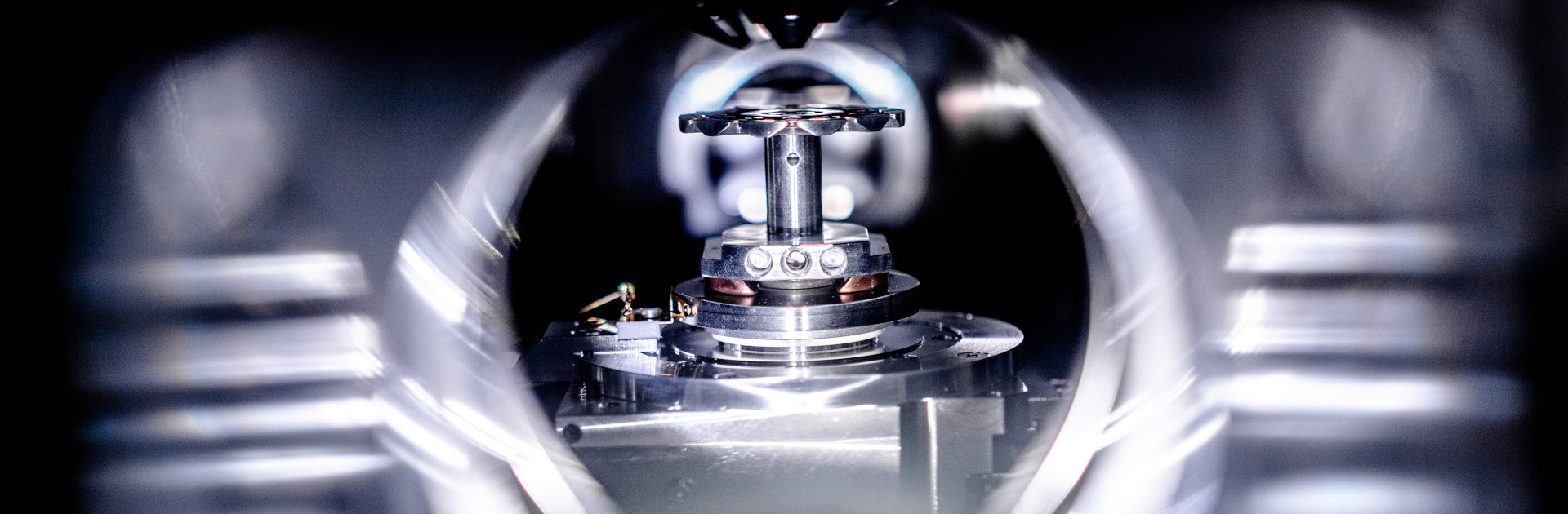

Linseis L78 RITA quenching dilatometer

Used to determine basic phase transformation temperatures (e.g. Ac1, Ac3, Ms), experimental determination of austenite decay diagrams (ARA, IRA). Measurements in the temperature range -100 °C to 1600 °C. In addition to different heating and cooling rates, it is also possible to characterise the effects of deformation at higher temperatures on the subsequent phase transformation during cooling.